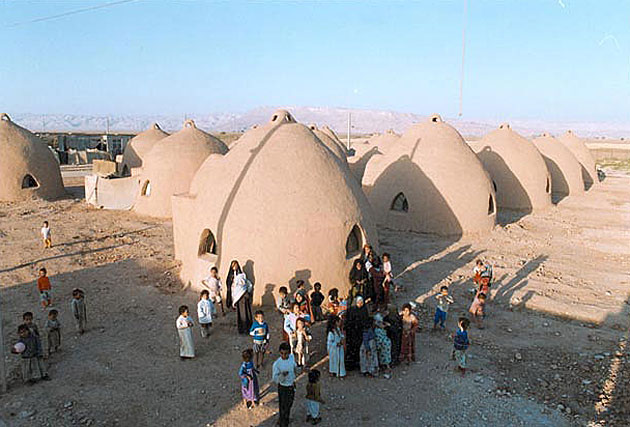

Superadobes

Almost a third of the world's population lives in dwellings made

from earth. As we become more concerned with our use of natural

resources, this is expected to increase. Advances in technology

now make it possible to very effectively build using superadobe

construction (the super-duper version of regular adobe

houses).

Superadobe |

|

The materials for a superadobe wall are simple - just barbed

wire and sandbags filled with earth. For eons, sandbags have been

the chosen materials for building dikes, and have also been used

for protection in war zones. Once these temporary structures served

their purpose, the sandbags were emptied and disposed of. Today,

superadobe (or superblock) construction is used for permanent

construction.

In the past, the main problem using sandbags for construction

has been that they lack tensile capability, which means that the

structures being built had to be low. It was also impossible to

create domes or arches. With superadobe construction, barbed wire

is placed between the layers of sandbags in order to create tensile

resistance. Shear stresses are transferred from one sandbag to

the next. Bigger sandbags can be used, so walls can be made higher.

It is also possible to create vaults, arches and domes.

Superadobe sandbags are

tubes made of fabric. They are filled with different

types of particulate, fluent material, which may include earthen,

organic sand along with manufactured or recycled materials that

then become self-supporting, forming into a block. The bags themselves

are coated with protective materials, meaning that durable exteriors

do not need to be shielded.

Because of the flexibility of the sandbag, monolithic structures

can be built in curved forms, completely from earth. Most traditional

roofing systems can be eliminated.

Single-curvature and double-curvature

compression shells don't transfer stresses from

element to element. Instead, stresses are transferred along the

structure's surface. With beam and column construction, when a

single element becomes overloaded to the point of failure, adjacent

elements are affected, and they all fail. This frequently results

in the collapse of the entire structure. With a domed structure,

excessive loads are shed with localized failure and the remainder

of the structure remains intact.

Live-load and dead-load stresses transfer to the ground, spreading

evenly along the dome or bearing wall's perimeter. With beam and

column structures, the loads get transferred by way of a footing

underneath each column. This results in severe stresses to the

upper structure that can cause cracking, particularly when there

has been frost-heave. This is why most foundations go below the

frost line. In a monolithic structure, frost-heave and differential

stressing don't present these problems. The structural load is

distributed over a larger area, so "soft spots" in the

soil have negligible effect.

One of the greatest challenges

in modern construction is creating structures that

will withstand natural disasters like earthquakes. As our climate

changes, this will continue to be of concern. The basic shape

of most structures creates problems, since the weight of the structure

is not evenly distributed between roof and foundation.

Frequently, there is a good deal more weight on the upper floors,

and deep foundations and footings can come apart at the structure's

base. There are designs that can provide shifting capabilities,

but they are often cost-prohibitive. A vaulted or domed structure

can be expected to be much more stable in the event of an earthquake.

The continuous foundation can actually slide across the ground

as it moves, while the upper structure resists damage.

Conclusion

Superadobe, using hand-filled or pump-filled sandbags combined

with four-point barbed wire, is a highly effective construction

method. It is eco-friendly, and lends itself very well to structures

that can be designed to withstand even earthquakes.

|